Swiss Alps SteamTechnologies

- - - - Deep engineering, deep innovation, deep interest in steam loco tech - - - -

Boiler feed pump

We set ourselves the goal of developing a steam-powered piston pump for boiler feeding that meets the following criteria:

- Sizes ranging from small model versions to original sizes

- A uniform control principle for all sizes

- Also available in model versions with proportions similar to the original, i.e., no external drivers on the piston rod

- Purely pressure-operated reversal

- Simple and economical to manufacture

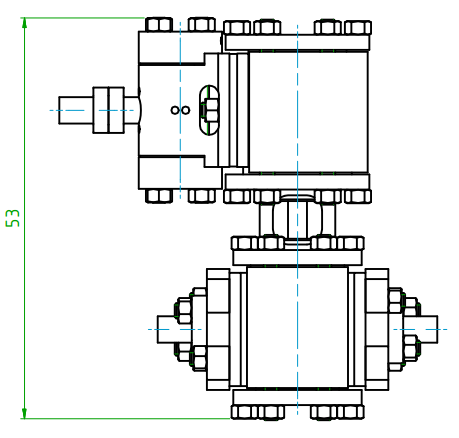

Boiler feed pump, 52 mm high,

prototype for the development of the control system

Manufactured a long time ago using

a lathe, sheet metal caliper, and file

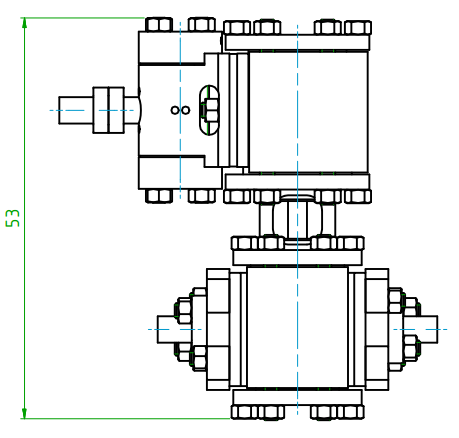

Boiler feed pump, 574 mm high,

delivery rate approx. 0.7 liters per double stroke

Status: Operational

The result of this development is a novel control system that requires only a single control valve.

Conventional steam-powered piston pumps have at least two control valves and a correspondingly complex control housing.

Instead of the second control valve, our solution contains only a few very simple components that have a minimal impact on overall manufacturing costs.

The large version is also designed for oil-free operation, so that no contamination occurs and the used steam can be returned to the feed water without further treatment.

With regard to the large version, we have received around 10 inquiries from hobbyists (who are interested in using it as a compressor), as well as one industrial inquiry and contact from a company in the alternative energy sector that operates a historic steam engine for its own purposes.

The following short film clip shows the prototype being tested:

The first running phase shows the pump feeding. It is no longer possible to determine exactly what settings were used in the last running phase shown. The control valve is usually as loud as in the first running phase shown.

Air pump / compressor

When using the solution as an air pump, additional effects must be taken into account.

Since there is occasionally a demand for air pumps in the narrow-gauge sector, the final development for this application is planned for the long term. However, without a specific order, the time frame for this is very broad.

Designed as a compressor for supplying

the compressed air brakes of rail vehicles

Status: Under development

During the initial development of the reversing valve, an incompressible medium was used as the transport medium.

During subsequent testing with (compressible) air as the conveying medium, an effect occurred that unfortunately made uncomplicated use as an air pump practically impossible.

We analyzed this effect purely theoretically and derived a measure to remedy it.

This measure eliminated the effect, but produced a new, undesirable opposite effect that could not be reliably remedied due to time constraints during the tests at that time.

To date, there remains the (as yet untested) possibility that the latter effect cannot be eliminated in a particularly elegant manner and could otherwise result in an externally visible, potentially unaesthetic additional expense and, furthermore, could reduce the efficiency of the pump.

Above all, it would have been difficult to conclusively determine whether the new effect would have been eliminated in principle or only due to a specific existing constellation of the various influencing parameters. This would have posed a considerable risk in the case of an order-related design (in an approvable version, i.e., with completely different materials and, as a result, significantly different design parameters), which would have made commercial pursuit of this development virtually impracticable.

In October 2015, the specifications we had set ourselves for the air pump solution were reviewed once again and then relaxed, resulting in a solution that gives us every reason to hope for a successful conclusion to the development process. So far, this is only available as a theoretical concept, but it can be parameterized to be completely safe in all important aspects. We currently estimate the residual risk of failure to be almost zero.

The solution does not require any significant dimensions for the additional parts needed, is quite simple, and can therefore be implemented with little effort.

This was the situation before 2019. Since then, a different, even leaner and significantly more practical approach has been pursued.

New approach from 2019

For use as a boiler feed pump, an old, very reliable US feed pump control system was “turned upside down” and simplified, which I knew nothing about beforehand.

It comes with a single control slider and, unlike the previous solution, does not require any other moving parts.

3D model

Status: Parts available, untested

Get in contact and see what is possible!