YK3-A: New valve gear without an open loop, with excellent diagram results

We created is a new design for steam locomotive valve gears which - in our opinion - is clearly superior to Walschaerts valve gear, both concerning maintenance requirements and also in the symmetry of valve events. It gives good diagram results even for large valve piston travel and avoids the disadvantages of open loops like with Walschaerts valve gear by omitting them.

All bearings are closed rotating bearings. The structure of the parts involved ideally is similar to the parts of Baker valve gear. The kinematical structure is similar to Walschaerts valve gear.

If you want to use this solution, please contact us before!

For a first implementation customer, we are open to give extensive support.

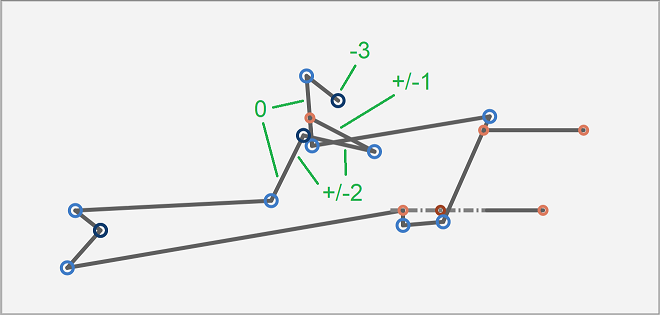

Below you see a preliminary implementation of our new valve gear version in our valve gear design software.

Please note that optimization rules are not completed in detail yet.

Run linkage: Right-click on the right in the "Move" menu (right mouse button)

Actuate reversing: Left-click on the left in the "Move" menu (left mouse button)

IMPORTANT: Reversing works in opposite direction at this state of implementation!

Recommended positions of the specific YK3-A valve gear parts or part sections in planes along Z-axis:

Some annotations about the relation to other valve gears:

Our solution is a combination of "Goelsdorf Winkelhebelsteuerung" (which kinematically is identical to Walschaerts but materially has a lever instead of the expansion link) and the "inversion" of "Helmholtz valve gear" (1) (2) which has the same vertical lever but uses a straight loop, also resulting in a virtual arc movement of the rear end of the radius bar when changing the degree of cylinder filling. This combination allows a much smaller radius of the lever replacing the expansion link than the one from Goelsdorf, so avoiding the real big disadvantage of Goelsdorf.

If the eccentric crank would be turned in opposite direction, the "expansion link lever" main bearing would have less stress (which is not very important when using modern roller bearings of the next size step is possible), but the valve event diagram would look much worse.

For high speed use, we recommend using a Helmholtz valve gear with linear roller bearings as expansion loops instead of our YK3-A valve gear, because of the latter one's up and down moving part of the expansion link replacement angular lever. Whereas the lower bearing point of the expansion link at Helmholtz valve gear rather should be set back like at Walschaerts valve gear.